Materials Needed for Food Coloring Tie-Dye: How To Tie Dye With Food Coloring

How to tie dye with food coloring – Embarking on the vibrant journey of food coloring tie-dye requires careful preparation. Gathering the right materials ensures a successful and enjoyable experience, allowing you to create stunning, unique designs on your chosen fabric. The process, while seemingly simple, benefits from a methodical approach to material selection.

Material Requirements for Food Coloring Tie-Dye

The following table details the essential materials, their purpose, and suitable alternatives, guiding you through the process with clarity and precision. Remember, the quality of your materials directly impacts the vibrancy and longevity of your tie-dye masterpiece.

| Material | Quantity | Purpose | Alternatives |

|---|---|---|---|

| 100% Cotton Fabric (T-shirts, pillowcases, etc.) | 1 item | Provides a natural fiber that absorbs dye effectively. Synthetic fabrics may not absorb dye as well. | 100% Linen, 100% Rayon (results may vary) |

| Liquid Food Coloring | Multiple bottles (at least 4-5 different colors) | Provides vibrant, non-toxic color for dyeing. Gel food coloring can also be used but requires more water. | Natural dyes (e.g., turmeric, beetroot) – these will produce less vibrant and more muted colors. |

| White Vinegar | 1 cup | Acts as a mordant, helping the dye bind to the fabric fibers for longer-lasting color. | Salt (1/4 cup per cup of dye solution) – less effective than vinegar. |

| Rubber Bands | Various sizes, depending on the desired pattern | Used to secure the fabric and create various tie-dye patterns. | String, twine – can create different textural effects. |

| Gloves | 1 pair | Protect your hands from staining. | Plastic bags (less effective, harder to work with) |

| Large Plastic Bowls or Buckets | At least 3-4 | Containers for mixing the dye solutions. | Large zip-top bags (suitable for smaller projects) |

| Squeeze Bottles or Spoons | Several | For applying the dye solutions to the fabric evenly. | Basting syringes (for more controlled application) |

| Plastic Drop Cloth or Newspaper | Sufficient to cover your work area | Protects your work surface from dye stains. | Old towels (less effective at preventing staining) |

| Washing Machine | 1 | For rinsing and washing the dyed fabric after the dyeing process. | Large container and plenty of water (requires more effort and water) |

Preparing the Fabric for Dyeing

Preparing your fabric correctly is akin to laying a strong foundation for a magnificent building; without it, even the most vibrant dyes may fail to produce the desired effect. Pre-treatment ensures that the dye penetrates the fibers evenly, resulting in rich, long-lasting colors that resist fading. Neglecting this crucial step can lead to uneven color absorption, dull hues, and premature color loss.Pre-treating the fabric involves removing any substances that might interfere with the dye’s ability to bond with the fibers.

These substances include sizing agents (added to fabrics during manufacturing to make them easier to weave), finishes (such as starches or softeners), and even residual dirt or oils. This cleansing process allows the dye to directly interact with the fabric’s fibers, resulting in a more intense and permanent color.

Fabric Washing and Sizing Removal

Effective pre-treatment begins with a thorough washing. This removes sizing, finishes, and any dirt or debris that might block dye penetration. Use a gentle detergent—avoiding anything with bleaching agents or fabric softeners—and wash the fabric in warm water. For particularly stubborn sizing, a pre-soak in a solution of warm water and a small amount of enzyme detergent can be beneficial.

After washing, rinse the fabric thoroughly until the water runs clear. Thorough rinsing is critical; any residual detergent can interfere with dye absorption. Allow the fabric to completely air dry before proceeding to the dyeing process. This ensures the fabric is clean and receptive to the dye.

Comparing Fabric Preparation Techniques, How to tie dye with food coloring

Different fabrics respond differently to pre-treatment. Natural fibers like cotton and linen generally require a thorough wash to remove sizing. Synthetic fabrics, however, may not need as extensive a pre-wash. Delicate fabrics, such as silk or wool, may benefit from a gentle hand-wash to prevent damage. Over-washing can weaken delicate fibers, leading to damage and affecting the final dye result.

The goal is to clean the fabric without compromising its integrity. For example, a heavy cotton canvas will tolerate a more vigorous washing than a sheer silk scarf. Always test a small, inconspicuous area of the fabric before washing the entire piece to ensure the chosen method doesn’t cause damage. For instance, a small swatch can be pre-washed to check for any color bleeding or shrinkage.

Applying the Dye to the Fabric

Applying the dye to your fabric is a crucial step in the tie-dye process, much like carefully preparing the ground before planting a precious seed. The method you choose will directly influence the final appearance of your creation, determining whether you achieve vibrant, saturated colors or a more subtle, blended effect. Careful application is key to unlocking the full potential of your dye bath and bringing your artistic vision to life.The process involves submerging your prepared fabric into the dye baths, ensuring complete saturation.

This requires a gentle yet thorough approach to prevent dye bleeding and achieve the desired color distribution. Remember, patience and precision are your allies in this stage.

The vibrant hues achieved in tie-dye rely on the dye’s ability to bind to fabric fibers, a process influenced by pH and temperature. Similarly, creating colorful icing requires careful consideration of color stability and ingredient interactions. For naturally derived colors, exploring options like those detailed in this helpful guide on natural food coloring for icing can enhance both projects.

Understanding these principles, whether for fabric or frosting, unlocks a world of creative possibilities with food coloring.

Dye Bath Application Techniques

Even saturation is paramount. To achieve this, begin by gently lowering a section of your fabric into the dye bath, ensuring that it’s fully submerged. Slowly and carefully work your way through the entire piece, making sure no areas are missed or only partially dyed. Use gloved hands or tongs to avoid staining your skin and to manipulate the fabric effectively.

For complex designs, work methodically, section by section, allowing each area adequate time to absorb the dye before moving on. The goal is a uniform color distribution within each dyed area, avoiding uneven patches or streaks. Imagine the dye as a gentle rain nourishing the thirsty fabric.

Preventing Dye Bleeding and Achieving Sharp Color Transitions

Dye bleeding can significantly impact the final result, creating blurry, indistinct lines where you intended sharp transitions. To mitigate this, consider the following: Firstly, ensure that your fabric is adequately wet before applying the dye. Secondly, work quickly and efficiently to minimize the time the dye spends on the fabric before rinsing. For sharp transitions between colors, use rubber bands or other tie-dye techniques to create distinct barriers between the dyed areas.

Imagine the rubber bands as carefully placed walls, separating the dye baths to keep the colors from mingling. Think of it as building a vibrant mosaic, each tile carefully positioned to avoid overlapping.

Optimizing Dye Saturation

To achieve deep, rich colors, allow the fabric to soak in the dye bath for the recommended time, usually between 30 minutes to several hours, depending on the dye and desired intensity. Regularly check the fabric to monitor dye absorption and ensure even saturation. Gently move the fabric around in the dye bath to prevent settling or uneven color distribution.

You can think of this process as a gentle dance between the fabric and the dye, allowing a harmonious union of color and material. After the soaking period, gently squeeze out excess dye without harsh twisting or wringing, which can distort the fabric or cause dye bleeding.

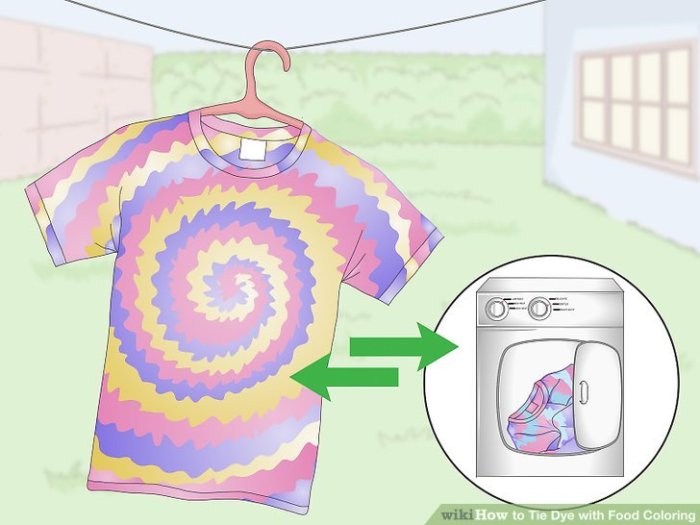

Setting the Dye and Aftercare

Securing the vibrant colors achieved through food coloring tie-dye requires a careful process of setting the dye and following specific aftercare instructions. This ensures the colors remain bright and the fabric retains its integrity, resisting fading and bleeding over time. Think of it as a sacred ritual, where the final steps are as crucial as the initial application of the dye.The process of setting the dye involves both heat and rinsing.

Heat helps the dye molecules bind permanently to the fabric fibers, while rinsing removes excess dye and prevents further bleeding or staining. Proper rinsing and drying techniques are equally important to maintain the vibrancy and longevity of the dyed fabric. Neglecting these steps can lead to disappointing results, such as faded colors or stained clothing. Let us consider this process a testament to patience and dedication, mirroring the devotion required in our spiritual practices.

Heat Setting the Dye

Heat setting is the crucial step in making your tie-dye colors permanent. This process uses heat to fix the dye molecules to the fabric fibers, preventing them from washing out. The most common method is to iron the fabric on a medium-high heat setting, using a protective cloth or pressing cloth between the iron and the dyed fabric.

Alternatively, you can tumble dry the fabric on a medium heat setting for 30-45 minutes. Imagine this heat as a divine blessing, solidifying the beauty of your creation. It’s essential to follow the fabric care instructions to avoid damaging the material during the heat-setting process. For example, delicate fabrics might require lower heat settings or air drying.

Rinsing and Drying Techniques

Thorough rinsing is essential to remove excess dye and prevent bleeding. Begin by rinsing the fabric under cold running water until the water runs clear. This initial rinse removes the majority of unbound dye. Subsequent rinsing can be done in a basin of cold water, changing the water frequently until the water remains clear. Avoid using hot water during the initial rinsing stages, as this could cause the dye to bleed.

Consider this rinsing a cleansing process, washing away impurities and leaving behind only the vibrant essence of your creation. Finally, gently squeeze out excess water – avoid twisting or wringing, as this can damage the fabric and distort the dye pattern. Air drying is preferred, but a gentle tumble dry on a low setting can also be used.

Again, always refer to the fabric care label for guidance.

Aftercare Checklist

Proper aftercare is essential to maintain the vibrancy and longevity of your tie-dye creation. Following these steps will ensure your beautiful piece lasts for years to come.

- Always wash your tie-dyed garment inside out in cold water.

- Use a mild detergent, avoiding harsh chemicals or bleach.

- Wash separately from other clothing to prevent color bleeding.

- Air dry whenever possible to avoid fading and preserve the vibrancy of the colors. The sun’s gentle touch can enhance the colors further.

- Avoid harsh scrubbing or abrasive cleaning agents.

- If machine drying is necessary, use a low-heat setting and remove promptly to avoid wrinkles.

Following these guidelines is akin to tending to a precious garden; gentle care ensures continued flourishing.

Troubleshooting Common Issues

Tie-dyeing with food coloring can be a fun and creative process, but sometimes things don’t go exactly as planned. Understanding the common problems and their solutions can help you achieve the vibrant, even results you desire. Let’s explore some typical challenges and how to overcome them.Uneven Color Distribution and Fading are two frequent issues encountered when tie-dyeing with food coloring.

These problems stem from various factors, ranging from insufficient dye concentration to improper fabric preparation and inadequate dye setting. Addressing these root causes is key to achieving consistent and long-lasting results.

Causes and Solutions for Tie-Dye Problems

Understanding the underlying reasons for uneven color distribution and fading is crucial for effective troubleshooting. A systematic approach, involving careful examination of the process, can pinpoint the problem and lead to a successful resolution.

| Problem | Cause | Solution | Prevention |

|---|---|---|---|

| Uneven Color Distribution | Insufficient soaking of fabric; uneven application of dye; insufficient dye concentration; using a fabric type that doesn’t absorb dye well (like synthetic fabrics). | Re-soak the fabric in water before re-applying dye; ensure even saturation by using a spray bottle or sponge; increase the concentration of food coloring; choose a natural fiber fabric like cotton or linen. | Pre-soak fabric thoroughly; use a consistent application method; use a higher concentration of dye; test dye on a scrap of fabric first; select appropriate fabric. |

| Fading | Insufficient dye setting; washing the fabric in hot water; using harsh detergents; exposure to direct sunlight. | Re-set the dye by following the setting instructions carefully (e.g., adding salt or vinegar); wash the fabric in cold water with a mild detergent; avoid direct sunlight exposure; air dry in the shade. | Properly set the dye according to instructions; always wash in cold water with a mild detergent; avoid direct sunlight exposure; store dyed fabric away from direct light. |

| Bleeding | Insufficient rinsing after dyeing; using too much water during rinsing; using a fabric that bleeds easily. | Rinse the fabric thoroughly until the water runs clear; use less water during rinsing; choose a fabric that is known for its colorfastness. | Rinse thoroughly after dyeing; control the amount of water used during rinsing; pre-test fabric for bleeding. |

| Muddy or Dull Colors | Using too much water when mixing dye; using low-quality food coloring; not enough dye applied. | Use less water when mixing dye; use high-quality food coloring; increase the amount of dye applied. | Use minimal water when mixing; use high-quality, vibrant food coloring; use sufficient dye to saturate the fabric. |

Question Bank

Can I use any type of food coloring?

Liquid food coloring generally works best, but gel food coloring can also be used, though it may require a slightly different approach to achieve the desired intensity.

How long does the color last?

Properly set and cared for, food coloring tie-dye can last for a considerable time. However, it may fade slightly over repeated washings.

What happens if I don’t set the dye?

The color will be less vibrant and much more likely to bleed or fade during washing.

Can I tie-dye synthetic fabrics?

While natural fibers like cotton and linen are ideal, some synthetic fabrics can be tie-dyed, but results may vary. Pre-testing on a scrap is recommended.